- November 29, 2024

- Posted by: admin

- Categories: Export Financing, Blog

Transporting goods across the globe is no small feat. The logistics industry relies on innovation to ensure goods are delivered safely and efficiently. One such innovation is the reefer container, a specialized solution for transporting temperature-sensitive and perishable goods. Think of it as a large, mobile refrigerator designed to maintain ideal conditions for cargo throughout its journey. This article explores the ins and outs of reefer containers, from their functionality and features to their importance in global trade.

What is a Reefer Container?

A reefer container, short for a refrigerated container, is an intermodal freight container equipped with a refrigeration system. It is specifically designed to transport perishable goods like fruits, vegetables, meat, seafood, and pharmaceuticals. These containers can maintain a temperature range from as low as -65℃ to 40℃, ensuring goods remain fresh and intact during transit.

Reefer containers rely on external power sources when stationed at ports or storage facilities. During transit, they are powered by diesel generators or other systems to maintain the desired temperature. Their advanced cooling systems enable seamless transportation of goods, regardless of weather or distance.

Also Read: Reefer Container Explained as Backbone of Global Trade

Features and Benefits of Reefer Containers

Reefer containers have transformed the way perishable goods are shipped globally. Here’s a breakdown of their notable features and benefits:

Precise Temperature Control:

Reefer containers offer accurate temperature regulation, essential for preserving perishable items. Whether it’s frozen seafood or chilled fruits, the required temperature is maintained throughout transit.

Durable and Weatherproof:

These containers are built to withstand harsh environmental conditions, ensuring cargo remains unaffected by external factors like rain, humidity, or extreme temperatures.

Partitioned Storage:

Reefer containers can be divided into compartments to store goods requiring different temperature settings, optimizing space and cost.

Compatibility with Multiple Modes of Transport:

Reefer containers can be transported via ships, trucks, and trains without requiring specific carrier vessels. This flexibility reduces logistical constraints and speeds up delivery.

Extended Shelf Life of Goods:

By slowing the ripening process and maintaining optimal storage conditions, reefer containers help extend the shelf life of perishable goods, reducing waste.

Reduced Need for Cold Storage Facilities:

Once a reefer container reaches its destination, goods can be unloaded without needing immediate cold storage, saving time and money.

How Reefer Containers Work?

Reefer containers operate on principles similar to household refrigerators but are designed for industrial-scale cooling. Their T-shaped decking system ensures even airflow from the bottom to every corner of the container. This uniform air distribution keeps the cargo at the desired temperature.

Key Components of a Reefer Container:

- Cooling Unit: Maintains the container’s internal temperature by circulating chilled air.

- Control Box: Allows operators to set and monitor temperature levels.

- Ventilation System: Ensures proper air exchange and removes harmful gases, such as ethylene, released by certain goods.

Airflow Requirements:

- Chilled Cargo (e.g., meat): Requires ventilated packaging to facilitate airflow and remove heat generated by the cargo.

- Frozen Cargo (e.g., fruits): Needs tightly packed arrangements to prevent gaps and remove external heat entering the container walls.

Atmosphere Control:

Reefer containers are equipped with advanced systems to manage oxygen, carbon dioxide, and ethylene levels. This helps prevent premature ripening, spoilage, or changes in flavor, especially for fruits and vegetables.

Types of Reefer Containers

Reefer containers come in various types, tailored for specific cargo needs.

1. Closed Reefer Containers

Closed reefers are the most commonly used type of refrigerated containers. They have an integrated cooling and heating unit that maintains the cargo’s temperature. These containers are fully sealed, ensuring consistent temperature control throughout transit.

Best Suited For:

- General perishable goods such as fruits, vegetables, meat, and seafood.

- Pharmaceuticals require a stable temperature range.

Features:

- Simple, all-in-one design.

- Available in standard sizes, typically 20 or 40 feet.

- Ideal for short to medium hauls.

2. Modified/Controlled Atmosphere Reefer Containers

These containers go beyond temperature regulation by maintaining specific atmospheric conditions. They use advanced technology to control oxygen, carbon dioxide, and nitrogen levels, prolonging the freshness of certain goods.

Best Suited For:

- Perishables like fresh produce, where prolonged freshness is critical.

- Goods sensitive to changes in oxygen and carbon dioxide levels, such as bananas or avocados.

Features:

- Equipped with systems that monitor and adjust gas levels.

- Extends the shelf life of goods significantly.

- Used for long-haul international shipments.

3. Automatic Fresh Air Management (AFAM) Containers

AFAM containers are a variation of controlled atmosphere reefers. They automatically adjust the intake of fresh air based on the cargo’s requirements, ensuring an optimal environment.

Best Suited For:

- Perishable items like flowers and fruits that emit ethylene gas.

- Goods needing precise humidity and air exchange rates.

Features:

- Advanced sensors to measure air quality and gas levels.

- Reduces the risk of over-ripening or spoilage.

- Enhances energy efficiency by minimizing unnecessary air circulation.

4. Cryogenic Cooling Reefer Containers

These containers use cryogenic materials like liquid nitrogen or dry ice to maintain ultra-low temperatures. They are particularly useful for transporting goods that need extreme cold, such as biological samples or high-value seafood.

Best Suited For:

- Goods requiring temperatures lower than -60°C.

- Pharmaceuticals and medical supplies, like vaccines and blood plasma.

Features:

- Independent of external power sources.

- Shorter operational lifespan compared to other reefers due to limited cryogenic material supply.

- Ideal for specialty goods requiring precise temperature control.

5. Redundant Refrigeration Reefer Containers

Redundant reefers are equipped with two or more refrigeration systems. If one system fails, the other takes over, ensuring uninterrupted cooling. This makes them suitable for high-value or sensitive goods.

Best Suited For:

- High-value pharmaceuticals or luxury food items like caviar.

- Critical cargo where temperature failure could result in significant financial loss.

Features:

- Dual cooling systems for added reliability.

- Typically used for long transits or sensitive cargo.

- High operational costs but ensures maximum safety.

6. Refrigerated Tank Containers

Refrigerated tank containers are designed for transporting liquid goods that require temperature control, such as milk, wine, or certain chemicals. They use circulating chilled fluids to maintain the desired temperature.

Best Suited For:

- Bulk transport of temperature-sensitive liquids.

Features:

- Cylindrical tanks housed within a container frame.

- Advanced insulation to minimize heat transfer.

- Monitoring systems to ensure consistent cooling.

Dimensions and Variants

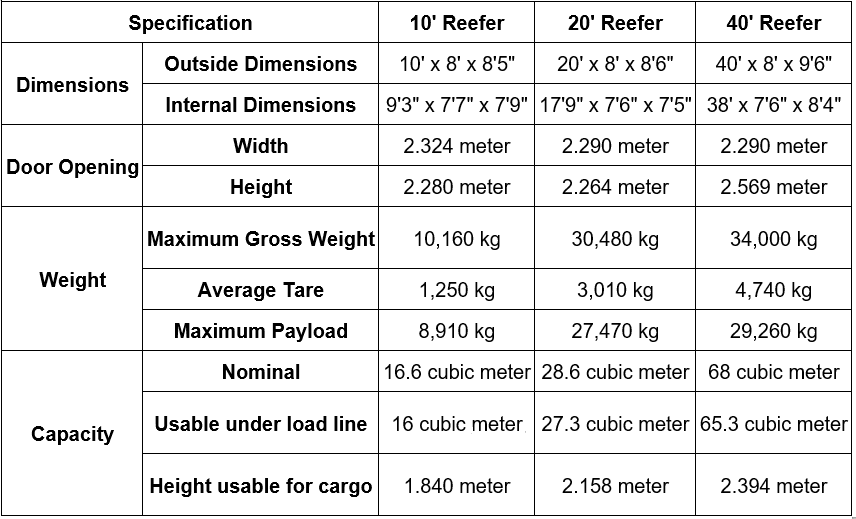

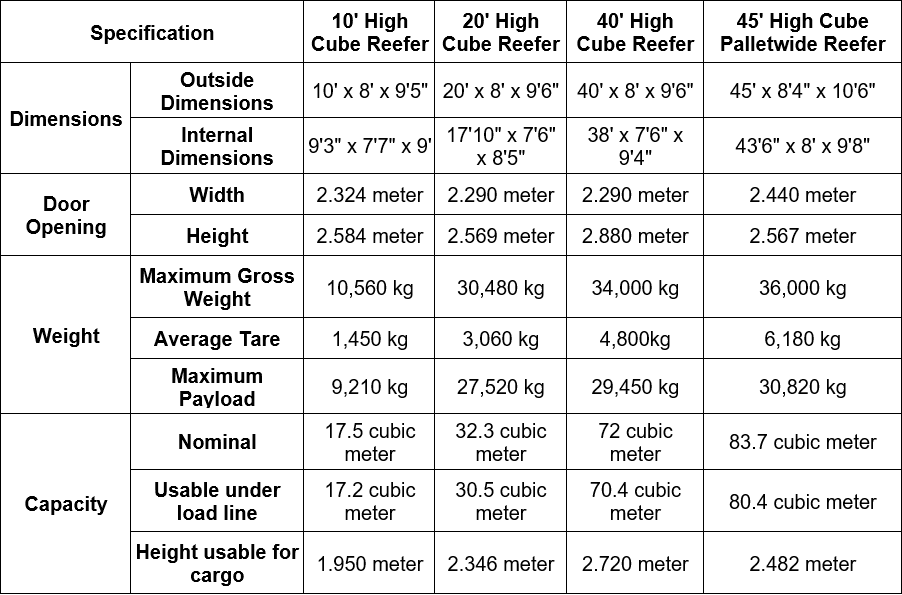

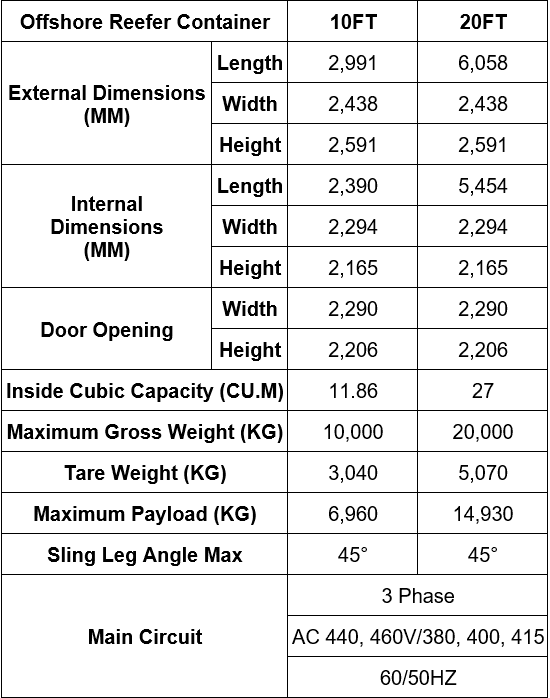

Reefer containers come in standard dimensions, with customizations available for specialized requirements:

Reefer Container – Dimensions

1. Common Reefer Containers

2. High Cube Reefer Containers

3. Offshore Reefer Containers

- 20-Foot Reefer Containers: Widely used in shipping, compact yet efficient.

- 40-Foot Reefer Containers: Offers more space for larger shipments.

- High Cube Reefer Containers: Taller for bulkier cargo.

- Dual/Triple Temperature Reefers: Allows separate temperature zones for different goods.

Cost of Reefer Containers

Reefer containers are more expensive than standard containers due to their advanced technology. Prices range from $7,500 (used) to $27,000 (new), depending on size, cooling mechanisms, and customizations.

Despite their high cost, reefer containers offer long-term benefits like reduced spoilage, better shelf life, and expanded market reach, making them a worthwhile investment for businesses dealing in perishables.

How Reefer Containers are Powered?

Reefer containers typically run on electricity provided by generators. These generators can be:

- Fuel-Powered: Common for long-haul transport.

- Electric-Powered: Environmentally friendly and efficient for shorter distances.

- Hybrid: Combines fuel and electric power for flexibility.

Backup generators are often included to ensure uninterrupted cooling, even during power outages.

Reefer Container Stowage Principles

Proper stowage is critical for optimal airflow and cargo preservation. Key principles include:

- Spacing: Leave gaps between pallets for vertical airflow.

- Packaging: Use ventilated boxes for chilled goods.

- Alignment: Ensure box vents are aligned for consistent airflow.

- Load Security: Secure pallets to prevent shifting during transit.

Difference Between Reefer Containers and Dry Containers

While dry containers are standard freight containers for non-perishable goods, reefer containers are designed specifically for temperature-sensitive cargo. Reefer containers are more expensive and technologically advanced, offering features like atmosphere control and precise cooling mechanisms.

FAQs About Reefer Containers

How much power does a reefer container consume?

Power consumption depends on the cargo, external temperature, and usage frequency. Newer models are more energy-efficient than older ones.

What is the temperature range for reefer containers?

Typically between -25℃ to +25℃, with advanced models achieving -60℃ to +40℃.

Are reefer containers airtight?

Yes, they can be made airtight by sealing floor drains and ventilation points.

Why are reefer containers white?

White reflects sunlight, minimizing heat absorption and reducing cooling energy needs.

Conclusion

Reefer containers have revolutionized global trade by enabling the safe and efficient transport of perishable goods. Their advanced technology, durability, and flexibility make them indispensable for industries like agriculture, pharmaceuticals, and food and beverage. Though they come with higher costs, the benefits they offer include extended shelf life, reduced spoilage, and expanded market reach, outweighing the investment.

With continued innovations in refrigeration technology, reefer containers will remain a cornerstone of temperature-controlled logistics, ensuring fresh and quality goods reach consumers worldwide.

Also Read: 21 Major Impact of Export Finance on Global Trade